Filter integrity test - a test method for cleanroom equipment and systems

With this test, also called filter leakage test or leakage test, the leak-tightness of the installed filter is checked by testing it with a reference aerosol (e.g. DEHS, Emery). The filter test in the installed state is carried out in the cleanroom using the same methods (aerosol generation, dilution and measurement) and basic principles as during filter production.

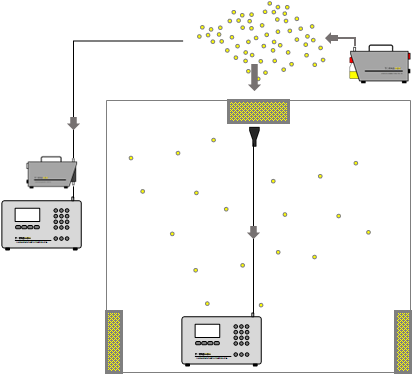

A reference aerosol (ATM 228) is applied in a sufficiently high concentration on the filter upstream side. The aerosol concentration is measured using a particle counter (CPA 341). First, a defined reduction in concentration is necessary using a dilution system (DIL 554/DIL 544) to the working range of the particle counter. On the downstream side, the filter surface is systematically scanned for possible defects using a sampling probe (SYS 529) and a particle counter.

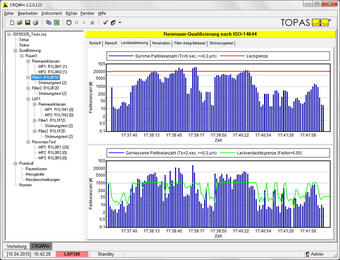

The measurement technology set for the acceptance of cleanroom systems (PDF) with the components ATM 228 aerosol generator, DIL 554 dilution system, CPA 341 particle counter, SYS 529 sampling probe, and the CRQWin cleanroom qualification software is ideally suited for the filter integrity test. With the new Cleanroom Particle Analyzer CPA 341, the cleanroom set is now state-of-the-art. We recommend this lightweight yet robust measuring device to anyone who values ease of use and intuitive operation in their daily work.