Diverse technologies for different tasks

Aerosols are ubiquitous. Either they are produced involuntarily through natural and anthropogenic processes or are synthetised to serve specific tasks. The behaviour of aerosols depends on their state of dispersion, i.e., on the form (including particle size distribution, material, morphology, charge) and the spatial distribution (including concentration) of the particles. Knowledge of these properties is the basis for many fields of work (occupational safety and environmental protection, research and development, testing and calibration) in which aerosols are important. Therefore, there is a high demand in industry, service companies, and government or scientific institutions for aerosol technologies for sampling, sample conditioning, and sample analysis.

Sampling

The starting point for the quality and reproducibility of any aerosol analysis is sampling, which must also meet specific requirements depending on the task. These include, among others:

- isokinetic sampling by means of suitable sampling probes (e.g. SYS 528, SYS 529) to avoid over or under estimation, especially of particles greater than 1 µm

- aerosol sampling from pressurised pipes and containers (SYS 525)

- taking aerosol samples from different locations (e.g. with sampling switching units SYS 520, SYS 520/S, or SYS 521)

- realisation of defined sampling volume flows (RFU 564)

Measures of conditioning

To avoid measurement artefacts and to protect the measurement technology used, targeted and defined measures of conditioning are usually required on the aerosol sample after sampling and prior to the actual aerosol analyses:

- reduction of the particle concentration (dilution) to the aerosol-analytical optimum (DIL 5XY, DDS 560, VDS 562) depending on the respective measuring principle.

- modulation of the aerosol charge state, e.g. targeted unipolar charging or neutralisation (EAN 581)

- removal of volatile organic components (TDD 590)

- loss-optimised sampling lines, e.g. electrically conductive lines (antistatic hose)

Sample analysis

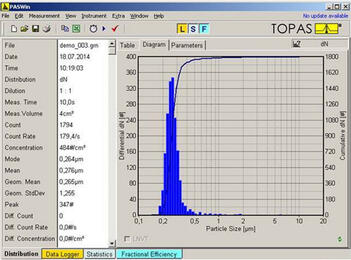

Only after sampling and conditioning does the actual particle characterisation concerning size and/or concentration take place. Depending on the analytical task, either individual devices are used or several techniques based on different physical measurement principles are combined for different size ranges. Therefore, we also have different technologies in our portfolio:

- light scattering spectrometers (LAP 322, LAP 323) according to ISO 21501-1 for time-resolved analysis of particle size and concentration from 150 nm – 40 µm for highly-resolved characterisation of emissions, or for monitoring tasks

- optical particle counters (LAP 340, LAP 340/L) according to ISO 21501-4 for time-resolved determination of particle size distribution and concentration for cleanroom applications, i.e., for lowest concentrations

- process aerosol monitor (PAM 510) for monitoring particle concentrations and mean particle diameter

- aerosol photometers (PAP 610, PAP 612) for the characterization of particle mass concentration in higher concentrated aerosols