Hospitals, validation service providers, hospital hygienists, and hospital pharmacies rely on our products—whether for initial acceptance of their clean environments or for regular inspections. General standards such as ISO 14644 apply in cleanrooms, and DIN 1946-4 and SWKI VA105-01 (SWKI 99-3 obsolete) apply specifically in the medical sector. They relate to:

- filter leakage test (during initial installation and, for example, after each filter replacement)

- recovery time measurements

- visual preliminary tests of the outflow behavior in the area of the uni-directional flow

- as well as the measurement of the degree of protection.

With devices for visualizing flows such as the CFG 291 fog generator, the successor model to the successful CFG 290, laminar or turbulent flow conditions in cleanroom areas become visible, allowing areas with insufficient air exchange, in which particles can accumulate, to be identified. In this respect, we recommend that our customers carry out flow visualizations both before commissioning and during regular qualification measurements of the cleanroom. For patients, surgeons, or pharmacists, it is extremely important to know the critical workplaces and to know that they remain free of contamination. Flow visualizations are therefore absolutely necessary/expressly recommended before commissioning a cleanroom. However, even if renovation work is carried out in the cleanroom or components are adjusted to new production processes, it must be proven that these do not adversely affect the airflows.

Acceptance testing of clean rooms using airflow visualization

Topas cleanroom equipment (PDF) not only complies with standards and guidelines, but also offers users state-of-the-art technology, practical design, and optimized handling. For us, this includes, for example, the suitability of testing technology for mobile use and the use of sterile, non-toxic fog for cleanroom acceptance testing using airflow visualization.

Visual verification of pressure cascades or the functionality of the exhaust filter is also possible. Please describe your application — together we will find a solution.

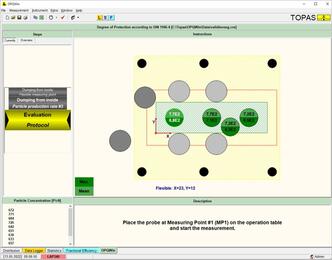

One of our experts accompanied a measurement service provider from Hygiene-Institut Mainfranken GmbH during its measurements to determine the protective effect of operating rooms in room class Ia in various clinics, for example in Potsdam and Chemnitz. Test aerosols can be generated and distributed in the operating room using combinations of devices such as aerosol generator and distributor. The CPA 341 ensures subsequent particle measurement. We would be happy to advise you further at this point. Give us a call or write to us.

In addition, three different scenarios were tested using state-of-the-art technologies to determine whether, for the purposes of patient protection, both the patient under laminar flow and the surgeon themselves are protected from contamination in terms of occupational safety. With the CFG 291, you can find leaks in transition areas of cleanroom elements, verify laminar displacement flow, or visualize the overpressure level in your own or your customers' cleanrooms.