Our strength is based on years of practical experience

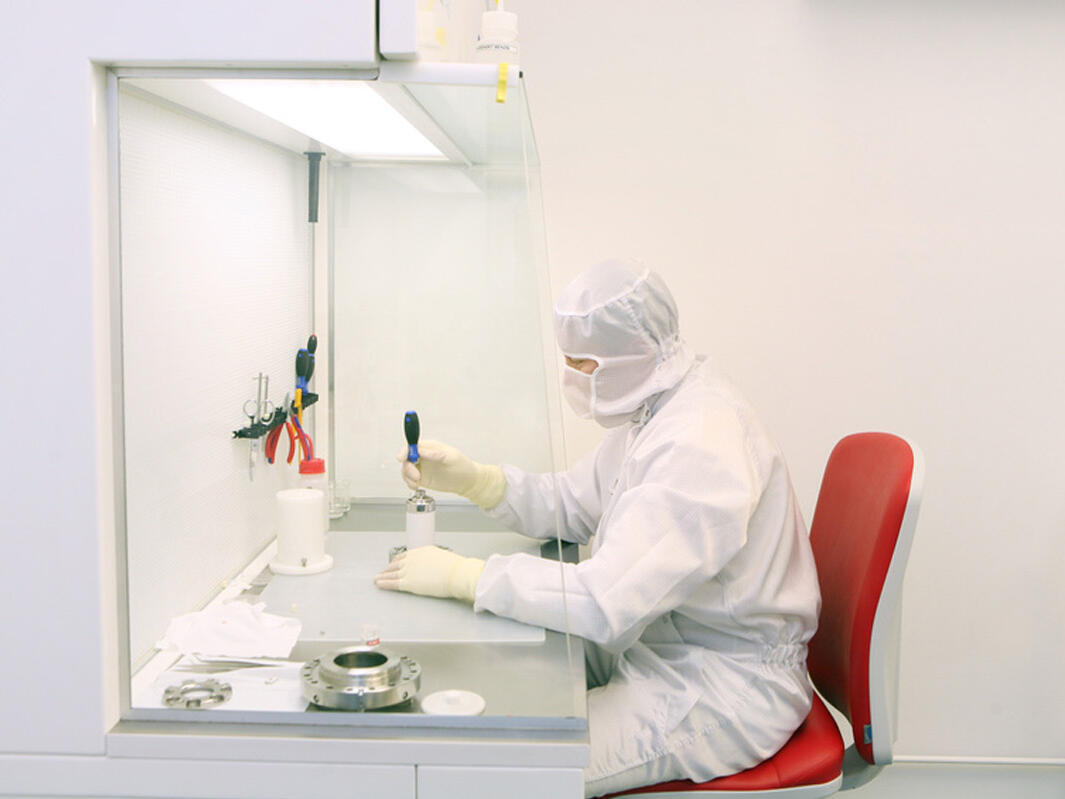

Your focus is on the highest level of precision, because you work in a cleanroom and are responsible for quality assurance there? We know that the regular testing of air filters, the certification of safety cabinets or cleanroom acceptance measurements can only be managed with technology you can trust one hundred percent.

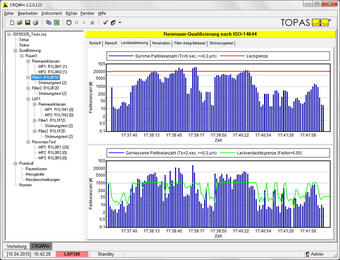

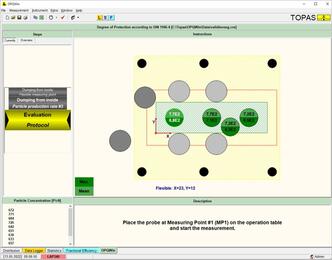

Test procedures for cleanroom equipment and systems:

- Classification

- Filter integrity test

- Recovery time measurement

- Flow visualization

- Protection level measurement

Topas devices test air filters in their installed state, whether they are complete ceiling filters or safety cabinets confined to a limited space. The operators of cleanrooms und ultra-cleanrooms depend on documented proof of compliance with defined limit values. To provide this, national and international authorities, as well as cleanroom operators and validation service providers from a wide range of industries turn to us:

- Pharmaceutical industry

- Medical technology

- Healthcare

- Microelectronics

- Food industry

- Aerospace

- Nuclear industry

- Agricultural industry

Since the early days, Topas has been a proven technology leader in this field: in more than 45 countries with more than 1000 customers. There are now more than 5000 aerosol generators and dilution systems in satisfied customer hands, making these our most important series equipment applications for decades. Also in the future we will continue to live up to the high standards we have set for ourselves and keep our focus in this field:

Our customers increasingly include (hospital) pharmacies that require clean rooms for sterile production. Safety cabinets are used here to manufacture drugs and medications in accordance with GMP guidelines. With our clean room set (PDF), you can carry out the acceptance of this small clean room quickly, accurately, and easily. You can read about the further tests that are possible with it in our overview.

There are no limits to what you can do in a cleanroom. Flow visualizations are used in urban and building planning or automotive development (body shape). Leak measurements of filters in ventilation systems in stables are also relevant. Thanks to a constant supply of fresh air, it is possible to reduce the risk of infection in animals and reduce the use of antibiotics.