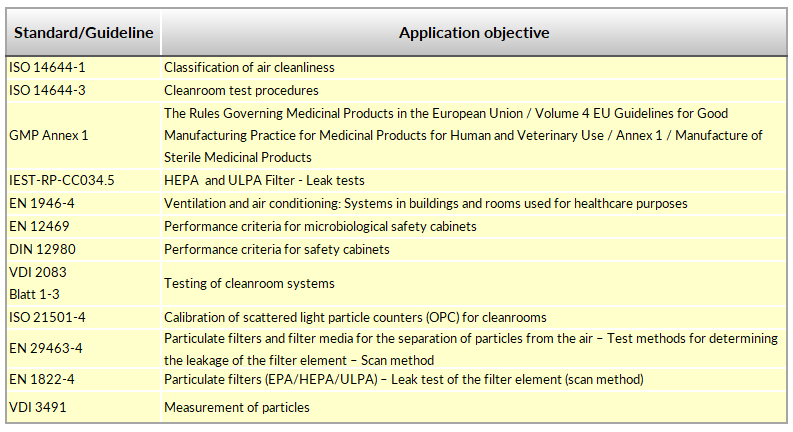

Standard series ISO 14644 requires various proofs that your cleanroom or your cleanroom facility meets the corresponding specifications. Various test routines are described in the standard, with the classification test being mandatory. This confirms cleanroom status. A particle counter determines the number concentration of particles by taking several measurements at different positions. Afterwards, the nominal cleanroom status can be confirmed or withheld in accordance with the specifications of ISO 14644-1. The appropriate technology solution is the particle counter CPA 341 and the CRQWin device control and data acquisition & evaluation software developed by Topas. Trust our experts.

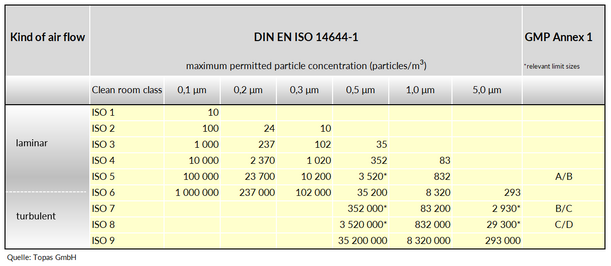

Cleanroom classes according to ISO 14644-1, GMP, and VDI Guideline 2083 are necessary in order to correctly describe the purpose of the cleanroom and ensure that its requirements are met. During the classification test, the particle concentration is measured at various points in a cleanroom, depending on the room area. The different measuring points are sampled with ambient air over a certain period of time. Finally, the measured values obtained are compared with the limit values of ISO 14644-1 to verify the cleanroom class. We recommend the CPA 341 Cleanroom Particle Analyzer as a measuring device: lightweight, robust, easy to use, and intuitive to operate.

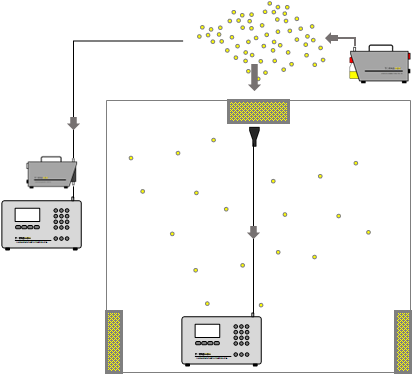

With this test, also called filter leakage test or leakage test, the leak-tightness of the installed filter is checked by testing it with a reference aerosol (e.g. DEHS, Emery). The filter test in the installed state is carried out in the cleanroom using the same methods (aerosol generation, dilution and measurement) and basic principles as during filter production.

A reference aerosol (ATM 228) is applied in a sufficiently high concentration on the filter upstream side. The aerosol concentration is measured using a particle counter (CPA 341). First, a defined reduction in concentration is necessary using a dilution system (DIL 554/DIL 544) to the working range of the particle counter. On the downstream side, the filter surface is systematically scanned for possible defects using a sampling probe (SYS 529) and a particle counter.

The measurement technology set for the acceptance of cleanroom systems (PDF) with the components ATM 228 aerosol generator, DIL 554 dilution system, CPA 341 particle counter, SYS 529 sampling probe, and the CRQWin cleanroom qualification software is ideally suited for the filter integrity test. With the new Cleanroom Particle Analyzer CPA 341, the cleanroom set is now state-of-the-art. We recommend this lightweight yet robust measuring device to anyone who values ease of use and intuitive operation in their daily work.

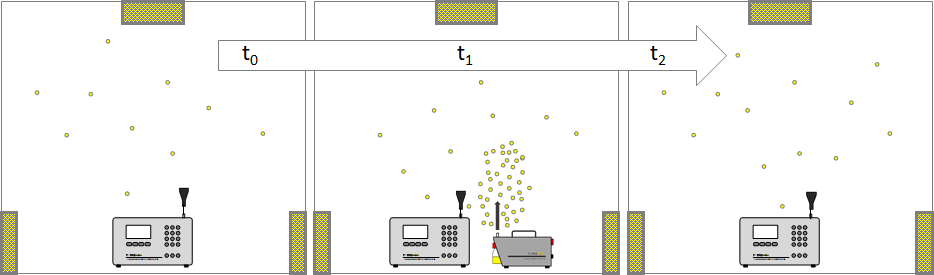

In order to remove potential particle contamination quickly, the air exchange rate in cleanrooms must always be sufficiently high. During recovery time measurement, test aerosols are introduced into the room. The decay curve of the particle concentration and thus the recovery time of the room to the original concentration level is then measured. With this Topas technology, you will be successful in your recovery time measurements: ATM 228 aerosol generator, CPA 341 cleanroom particle analyzer, CRQWin cleanroom qualification software.

Flow visualization

Devices for visualizing airflows, such as the CFG 291 fog generator, make laminar or turbulent flow conditions in cleanroom areas visible. Measurement objectives in practical applications include:

- Flow type

- Locating flow dead spots

- Visualization of pressure cascades in the clean room

If you are interested in learning more, we recommend our information on testing operating rooms.

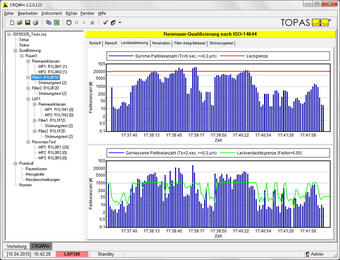

Our software for the guided evaluation of cleanrooms

Our central software systems CRQWin (ISO 14644) and OPQWin (DIN 1946-4) combine the full range of validation hardware in use and are capable to communicate with a wide variety of available particle counters. Call us for an exact specification of which models we support.