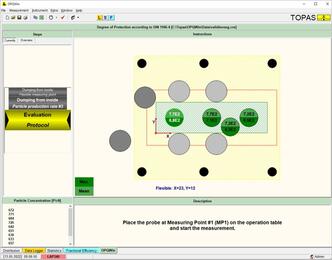

The energy efficient, smaller variant of a cleanroom – the safety cabinet – is subject to equally demanding checks as a process room. As a leading manufacturer of precision instruments, Topas offers a comprehensive and high-quality product range for acceptance measurements (filter integrity tests, flow visualisations) of entire rooms as well as spatially delimited safety cabinets.

For flow visualisations or filter integrity tests for your safety cabinets, take advantage of our state-of-the-art cleanroom equipment set, its sensible design and optimised as well as mobile operation.

Take advantage of the latest technology in our cleanroom equipment set (PDF), its practical design, and its optimized and mobile handling for these tests on your safety cabinets.

We would be pleased to provide you with further information on various test procedures for cleanroom equipment and systems.

With the particle counter method, the smallest leak in the filter can be detected. In addition, less filter loading with test aerosol is necessary because the optical single particle counter already used in the classification procedure is much more sensitive than the integrally working photometer. Topas follows the normative recommendation with this methodology.