Where even low particle loads disturb or even harm people or a product, it is essential to find a modified ventilation concept with improved separation performance, and it is essential that these filters are 100% checked. This especially applies to HEPA and ULPA filters, which are used in applications with the highest demands: for example, when handling viruses at safety workbenches (for personal protection) or for product protection, as known from the chip and pharmaceutical industries. Today, such highly efficient filters can also be found in high-end household appliances. With our test systems, we guarantee the manufacturers a production-accompanying test at the level of the technology leader.

Hot topic 100 % inspection during production

Are you looking for a technology to test medical filters, respiratory filters, passive smoke filters or smoke evacuation systems as part of inline or online testing? We are experts in this field. We will be pleased to explain to you exactly what we can do and how quickly our technologies for filter tests can be used in the ongoing production of medical and other filters.

Fully automatic filter testing during ongoing production

Driven by our customers and their needs, we are constantly developing in the field of filter testing. See here the latest developments in the field of

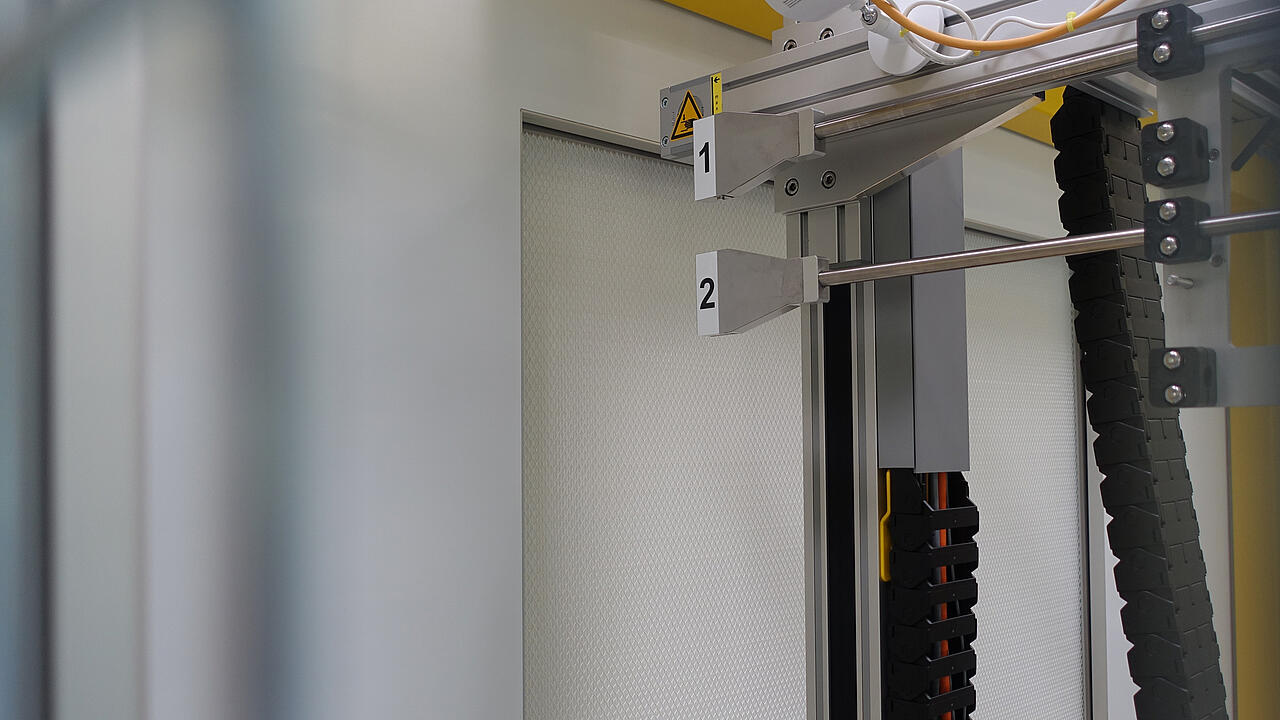

Filter scanners for highly effective EPA, HEPA and ULPA particle filters

With our systems, you can test not only filter elements, but also filter media. Save yourself the investment in an additional filter media testing system and test the product quality of your filter media suppliers at the same time.

The manual or automatic filter test technologies AFS 150, AFS 152, and AFC 132 QC HEPA, as well as the AFS 155 Oil Thread Leak Test System for HEPA filters offer the following possible test routines:

- integral separation efficiency

- local separation efficiency

- leakage detection

- differential pressure behaviour

Our software – a multitool

Topas’s proprietary PAFWin test system control, data acquisition & evaluation software for controlling the aerosol instruments involved and for data acquisition reliably guides the operator through the entire test sequence and finally generates a test report. All of the performed tests are stored in a database that enables traceable quality assurance during filter production.

Success project 1

For the 100% inspection of diverse types of filters with correspondingly high production output, we can now boast more than 100 test stand installations within an international supply chain. The end customer benefits from this: he can trust the measurement reliability with his supplier network and can also pass this on to his customers as a seal of quality.

Success project 2

A leading manufacturer of HEPA filters equipped eight international locations with our filter scanners. Today, he can give his customers a credible promise of quality by operating all laboratories identically with one testing system.