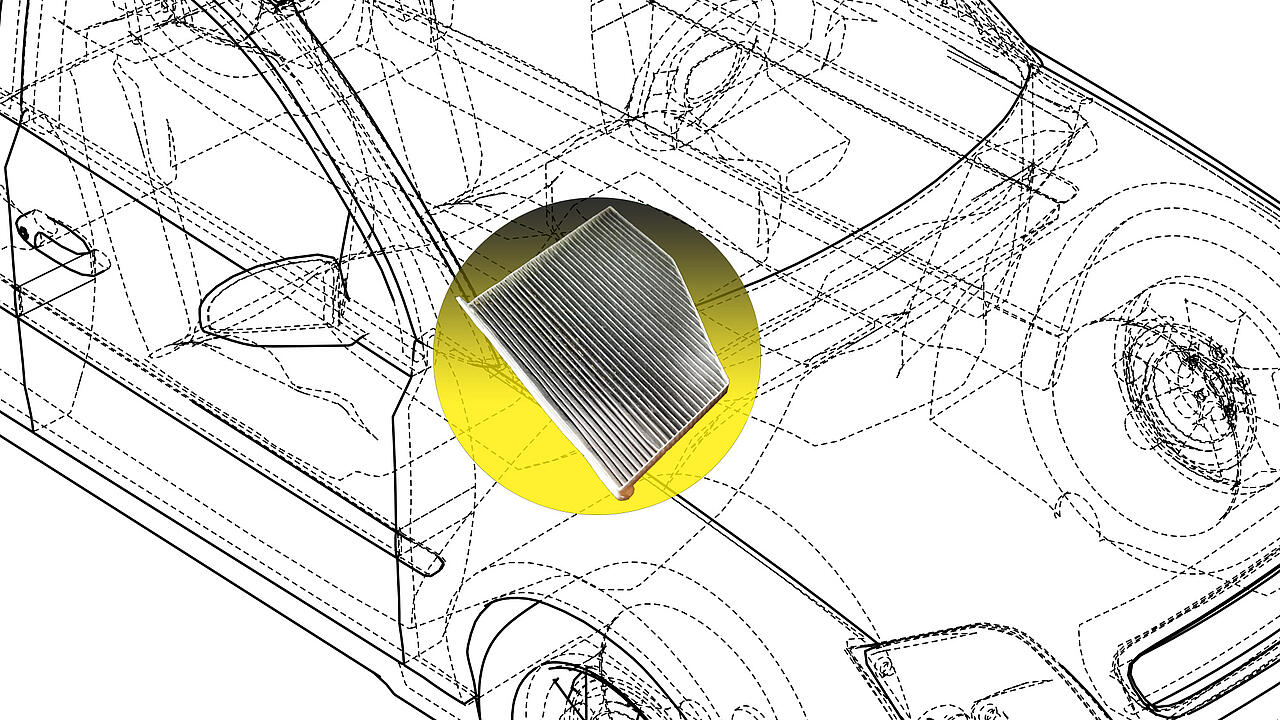

In the course of their life, a person will spend several years in the car – an important reason to ensure well-balanced and good quality air in the vehicle. In-cabin air filters have been around for decades – for 30 of those years we have been working with manufacturers, and consequently know their requirements in detail. Our technology has grown over the decades to both meet and keep pace with the changing customer demands in the industry. That’s why you can rely on the products from our company to feature innovative technology and meet the highest requirements, whether they are test stands or measuring instruments for validating air filters.

We place the same demands on the interior climate in motor vehicles as we do on the climate inside buildings. The same applies to cabin air filters, which are now found in every vehicle. From the former pure “pollen filter” to the later relevant separation of fine particles such as soot or dust to gas filtration, the expectations placed on air filters, both by manufacturers and society, are now comparable to those of air conditioning systems. These are the fields in which you operate and your customers, the producers of all types of motor vehicles, expect impeccable cabin air filters from you? As a test institute for quality assurance in filter production or in the field of motor vehicles you are responsible for proving that filter media are effective without restriction? Or do you work in research and test filter media and materials in order to further develop and optimise them? Then you have come to the right place. Topas system solutions test cabin filters as quality control or production-accompanying in defined sampling intervals. We offer these technologies to filter and filter media manufacturers as well as to testing institutes.

Find a solution for your application

Current trends in the development of filters and separators in the automotive industry and their quality-oriented testing place high demands on standard-compliant and automated testing technology, which we successfully meet with our wide range of filtration testing equipment. Topas test systems are state of the art and measure the separation performance of cabin air filters against particles and gases individually or in combination.

Testing routines for the evaluation of particle separation

- Differential pressure test

- Gravimetric separation efficiency test

- Dust loading capacity

- Measurement of fractional collection efficiency

- Determination of PMx-based collection efficiency

Instrumentation implemented in the test system

- ATM 222 Aerosol Generators

- SAG 410 Dust Disperser

- EAN 581 Bipolar Aerosol Neutralizer

- LAP 323 Optical Aerosol Spectrometer

- DIL 545/C and DIL 545/B Dilution System

Instrumentation implemented in the test system

- MFC 594 Gas Controller & Converter (NH3, H2S)

- LGC 595 Liquid Dosing Gas Controller (Toluene, Ethylacetate)

- EGC 596 Evaporation Gas Controller (Acetaldehyde)

- MGC 597 Mixing Gas Controller (NO2/NOx)

Additionally, suitable gas measuring systems can be used.

Installation of a PAF 113 test system for both particle separation and gas absorption/desorption of of air filters for passenger compartments

Have you ever wondered how long it takes to set up a PAF 113 test system for particle separation and gas absorption? No longer than 30 seconds – at least in this video from Bangkok where our colleagues have worked on an installation at the premises of an important global customer from the filter industry.

Our software to easily handle testing equipment

The PAFWin test system control and data acquisition & evaluation software, developed by Topas and running under Windows, ensures that the handling of test equipment and the performance of accurate and reproducible tests remains easy. Contact us for an exact specification of which additional devices and test sequences PAFWin supports with its software components.

Our testing systems in the application area of cabin interior filters comply with relevant standards and guidelines, such as DIN 71460-1/2 (draft) and ISO/TS 11155-1/2.

We developed our first cabin air test system for gas and particle measurements back in 1995. Today, we have installed more than 60 PAF series test systems in over 10 countries.