Technological solutions built on four decades of intensive research

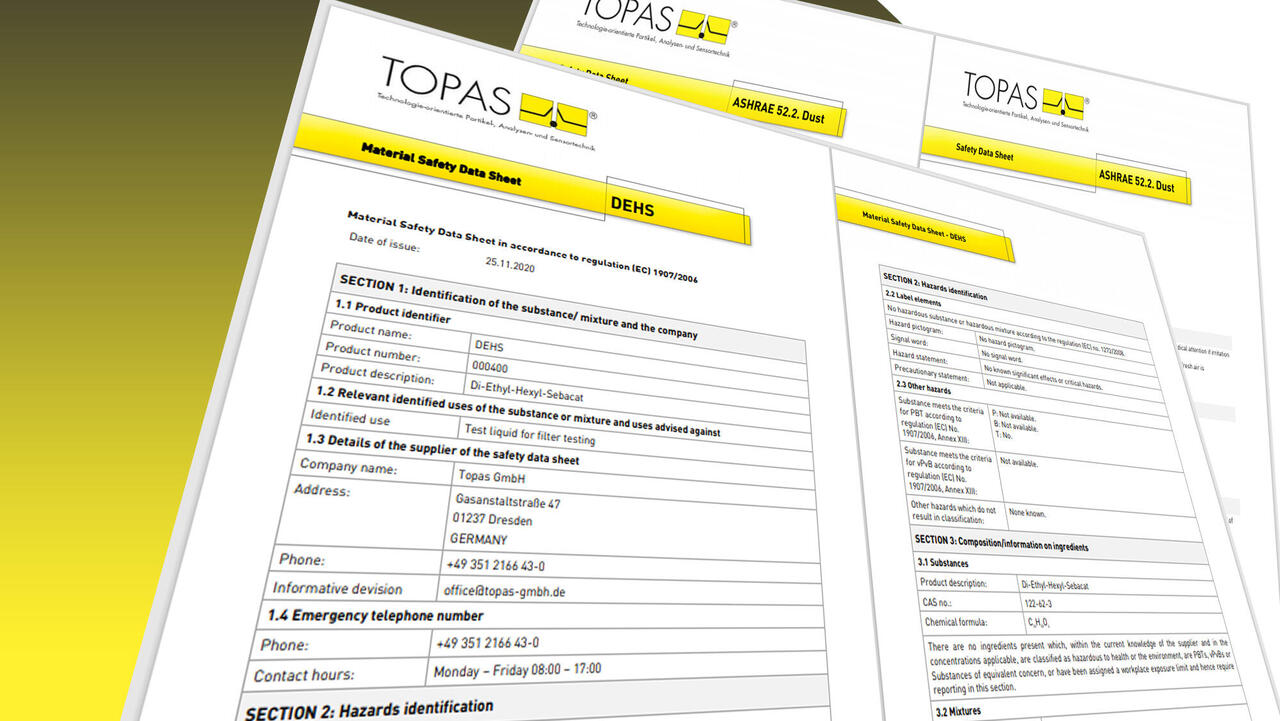

Using Topas preparation technologies and analytical instruments for disperse material systems (suspensions, powders, emulsions), a wide variety of physico-chemical properties can be determined for substance characterisation. These include, among others, the deagglomeration behaviour, the particle size distribution, the particle concentrations or the coarse fraction. These characteristics are used, among other things, in development, quality control or safety data sheets in accordance with the REACH Regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals). Sample fractionation of an analytically more precise evaluation is a further field of application. Contact us – together we will find your solution.

The Topas laboratory on your desk: modular and smart preparation and analysis technologies

Preparation technologies from our company include ultrasonic disintegrators, vibrating screen exciters for microsieving, dry dispersion or bulk solids analysis. We also show diversity in our spectrum of analytical instruments such as liquid particle counters, aerosol spectrometers or pore size measurement systems.

- industry (quality controls for incoming and outgoing wares)

- chemical, biological, medical

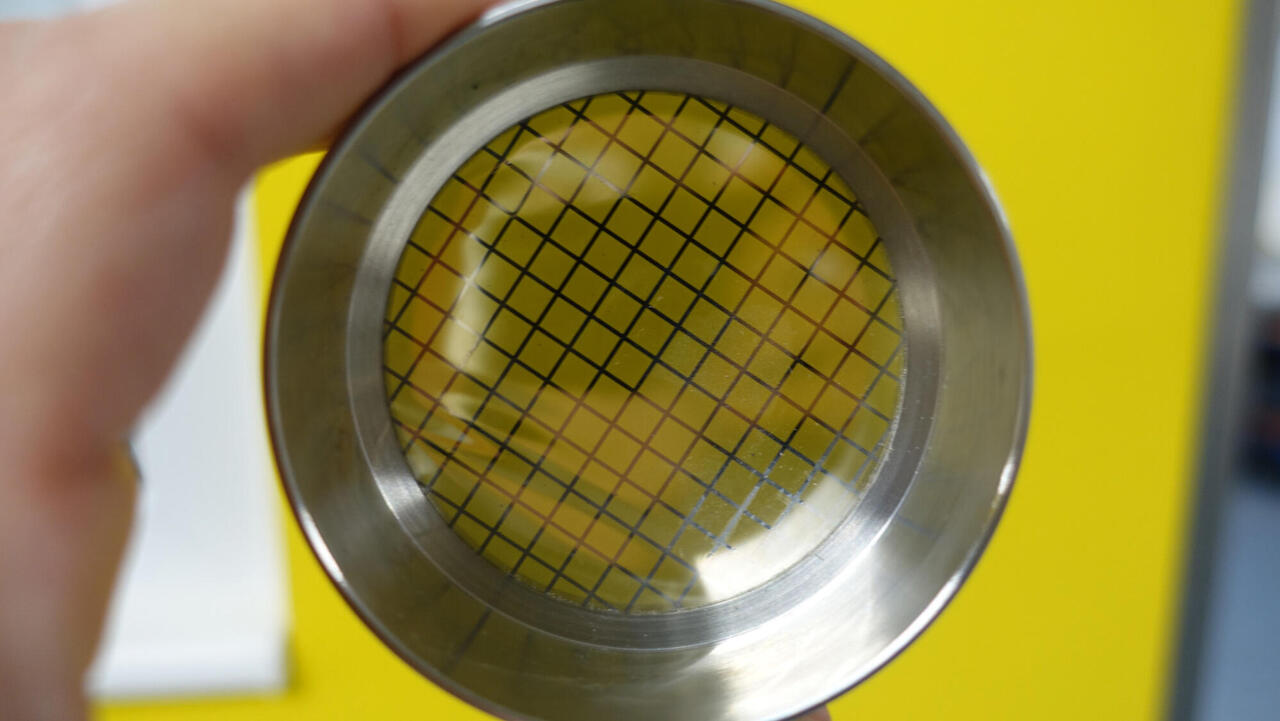

- semiconductor industry

- automotive industry

- food industry

- cosmetics industry

- research

- analysis laboratories

- scientific institutes

- industrial investigations

- government agencies

- environment

- occupational safety

- consumer protection

In determine the characteristics of powders and suspensions in the best possible way, a defined and reproducible dispersion is required. The state of dispersion, i.e., particle concentration and particle size distribution, can be analysed by existing measurement technologies but also with our analytical instruments.

We provide you with competent technologies for analytical preparation:

Dispersion technologies

- ultrasonic dispersion (UDS 751 Ultrasonic Disintegrator)

- aerosolisation of powders/dusts (SAG series)

- aerosol generation from liquids, solutions, and suspensions (ATM series)

Analysis of particle size distributions and size fractions

- analytical microsieving (EMS 755 electromagnetic sieve vibrator)

- Aerosol scattered light spectrometry (LAP 323 laser aerosol spectrometer)

As a spin-off from the Technische Universität Dresden, the founders of Topas were already involved in the field of particle size analysis (granulometry) in the beginning of the 1980s. Our LAP 323 Aerosol Spectrometer, which is still in use today, is thus one of our first proprietary technologies and impressively demonstrates almost 30 years of experience.