“Engineering is hard. “, a German saying claims. Jan Müller, development engineer and leader of the research and development team at Topas, has heard it said, but he but doesn't actually agree with it very often. The graduate physicist and passionate engineer has been working at the aerosol and particle specialist since 2011 and, like some of his colleagues, started his job at the technology-oriented mid-sized company via a funding program as an innovation assistant. Jan Müller is a development engineer at Topas and, since 2022, also head of the research and development department, which is responsible for the development and improvement of series devices and test systems.

The creation of a device – from a customer idea to a series device

"Jan Müller takes us through the multi-state process that a device takes on its way to development." At the beginning of the conceptual design, the customer’s needs are on the table and should be approached on the basis of initial project part sketches. This was the case with the newly developed FCS 249 calibration system. The goal was to produce salt aerosols of a certain size in order to use them to calibrate devices that perform exhaust gas measurements according to a new directive.

But how do you turn an idea into a device?

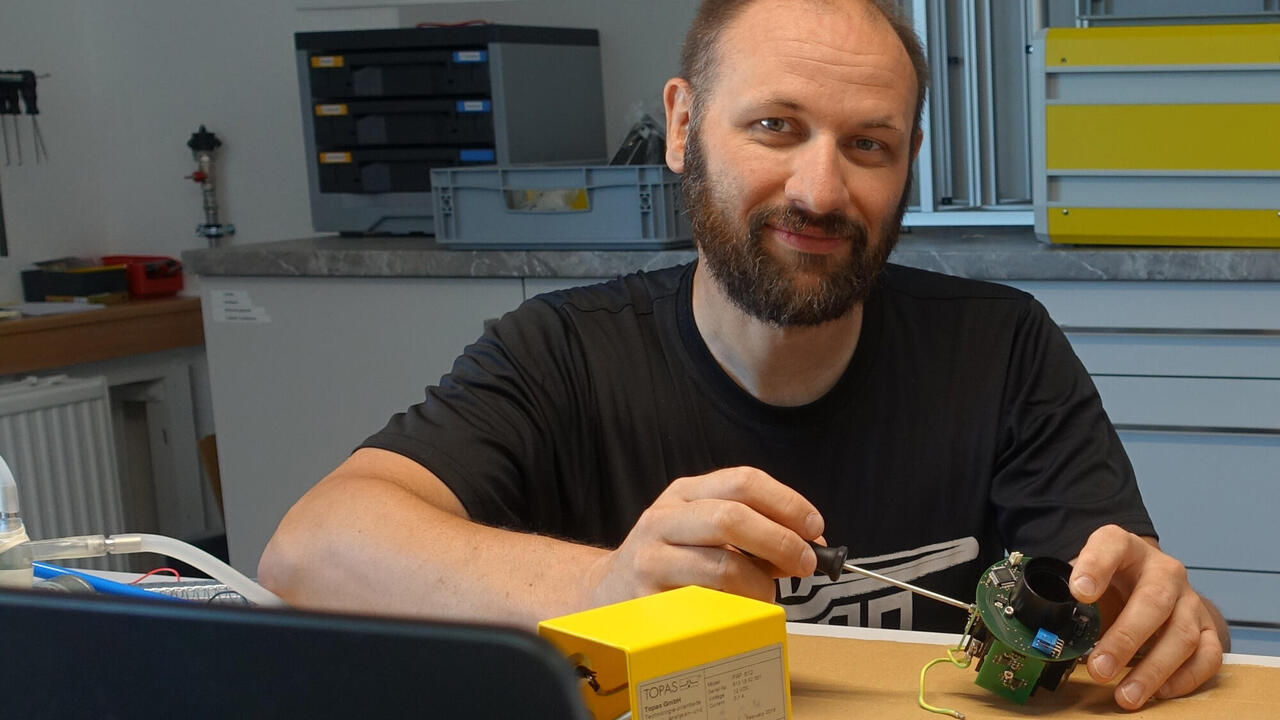

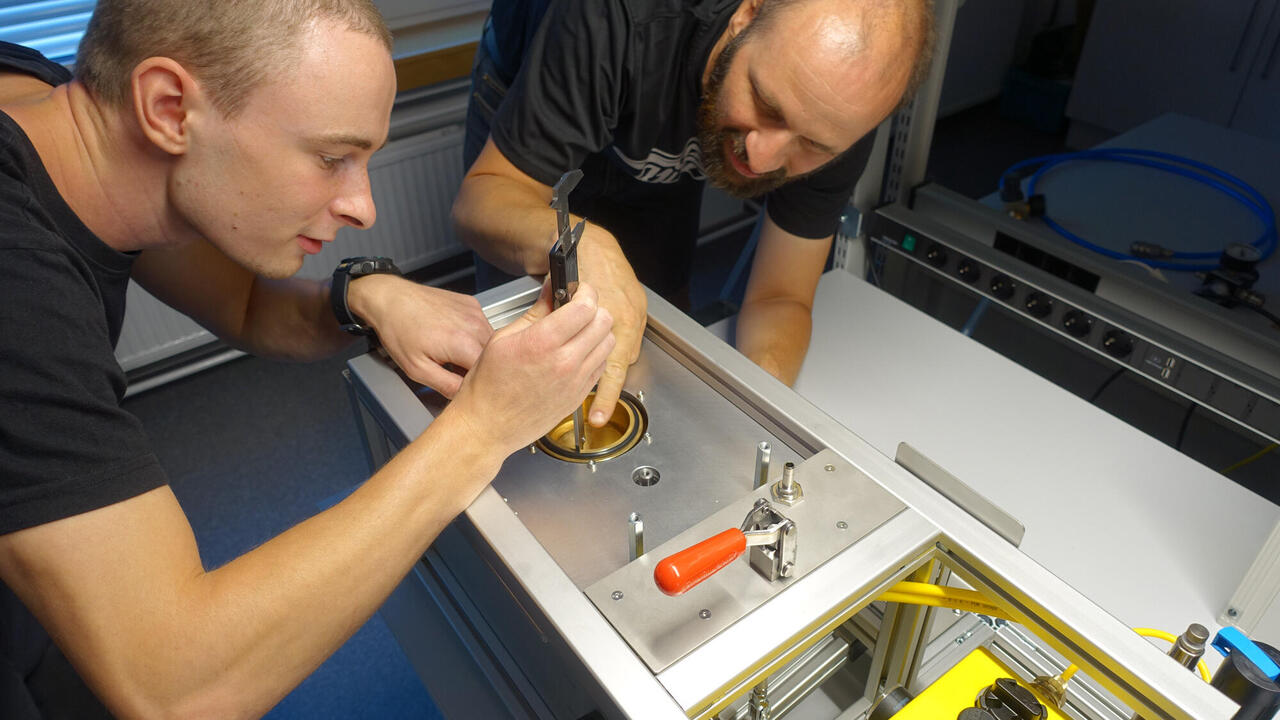

One possibility is 3D sketches. Often several ideas are run through in this phase, many things are presented in a simplified manner, and many things are set back to the beginning. Once the initial ideas have been modelled, the developers assemble various elements on the screen to create a device. The basic components of the so-called “demonstrator” that has been created in this process are manufactured externally. For simpler models or assemblies, the trained physicist also uses the in-house 3D printer. Now it’s time for “tinkering,” a popular activity for Jan Müller and his colleagues: they assemble individual parts and test the result in terms of functionality and other process specifications. After that, electronics is on the agenda: the developer designs program sequences or user interfaces, among other things. Printed circuit boards are programmed and examined from the user’s point of view in terms of user interface design and technical functionality. Not to be underestimated is the accompanying documentation, which makes up a considerable amount of the development project at Topas. The now finished prototype is ready for use in terms of functionality, design, programming, and electronics and can, in the best case, be handed over to the customer as-is. In reality, the development engineer usually has to make various adjustments, either on-site or via remote access.

If the device has market potential, conversations about series production begin at Topas and the device goes into the post-design phase.

In this phase, engineers look at such aspects as usability, component availability, production costs, ease of maintenance, or the simplest possible assembly and optimize a number of things, especially for their own production processes. Now, other colleagues from marketing and sales also come on board, feeding the product into the in-house developed data management Top-Office and taking care of product manuals, data sheets, and publication on the website. Here, the development engineer is hardly involved and is already waiting for new customer requests – or a completely new device that doesn’t exist, yet.

What makes an engineer at Topas?

If you ask Jan Muller about the key qualifications of an engineer, words like curiosity, panoramic vision, and the courage to find new solutions and implement them come up. Of course, enthusiasm for STEM subjects, good spatial reasoning, and, especially at Topas, an affinity for the topic of aerosols are essential. For this, the current head of R&D was given time and space during his induction and the chance to acquire basic knowledge of the niche industry at specialist seminars. He wants to develop technological solutions - no matter how crazy the task is sometimes. More important to the graduate physicist than design or drawing programs is often a direct and quick exchange with colleagues over a cup of coffee or a chat on the sun terrace of the Dresden company. The immediate proximity to the company’s internal research laboratories is also essential for his work. As an SME with around 100 employees, direct contact with customers is still possible, and that is precisely what the development engineer values so much about his work at Topas.

Freedom of action

It is not always the customers who approach Topas and provide the impetus for product development. The head of Research & Development is himself on the trail of unmet needs. Even when it comes to design development, he designs according to his own sensibilities, as with the VDS 562, a variable dilution system, or the FCS 249 calibration system. He appreciates the fact that his employer imposes few restrictions in terms of time. Only in this way is it possible for him to discover new technologies and also to be able to use them. As an example, Jan Müller mentions the ATM 228 aerosol generator as a development from the previous instrument, which is now one of the Topas’s bestsellers. The development engineer put his recipe for success – and the company’s – into a succinct statement: “innovation comes from freedom.”

When it comes to test systems and plant engineering, the researchers and developers at Topas are less involved. However, the head of R&D has also been involved in some exciting projects with heavyweights. For example, he and his colleagues were in charge of developing a technology for a global player to test filters in the extremely short measurement time of six seconds. They managed it in four seconds and are proud of their accomplishment. In the future, the development engineer can imagine many new paths – the freedom at Topas, for example, also allows him to try out whether robots can support Topas systems in automation tasks.

Crisis-proof in a niche industry – and plenty of potential for developers with passion

The last years since 2019 have been shaped my major global events such as the Corona pandemic. Topas has also felt these in the product area. Thus, mask media testing or exhaust gas measurements are two topics that resulted in the development of new technologies at Topas. For Jan Müller, these are wave movements and it is always necessary to reckon with their return flow. He, too, advocates a flexible way of thinking and broad positioning in the product range. As a consequence of the global political situation, Topas also has to contend with increasing delivery bottlenecks for finished parts. Here, the engineer has to improvise, look for alternatives and stock up with foresight wherever possible. This makes it all the more important, especially now, that research and development have long been seen and treated as an important pillar at Topas. This is explained by the fact that Topas sees itself as more than just an aerosol and particle measurement company. It sees itself as a problem-solver for its customers. The well-positioned R&D team is able to react quickly and can deal with problems more broadly. And that is what Topas customers can expect. Regardless of this, the company looks with pride on its own solutions, which are currently reflected in more than 30 patents, over 15 registered utility models and seven trademarks.

A playing field for all kinds of engineers

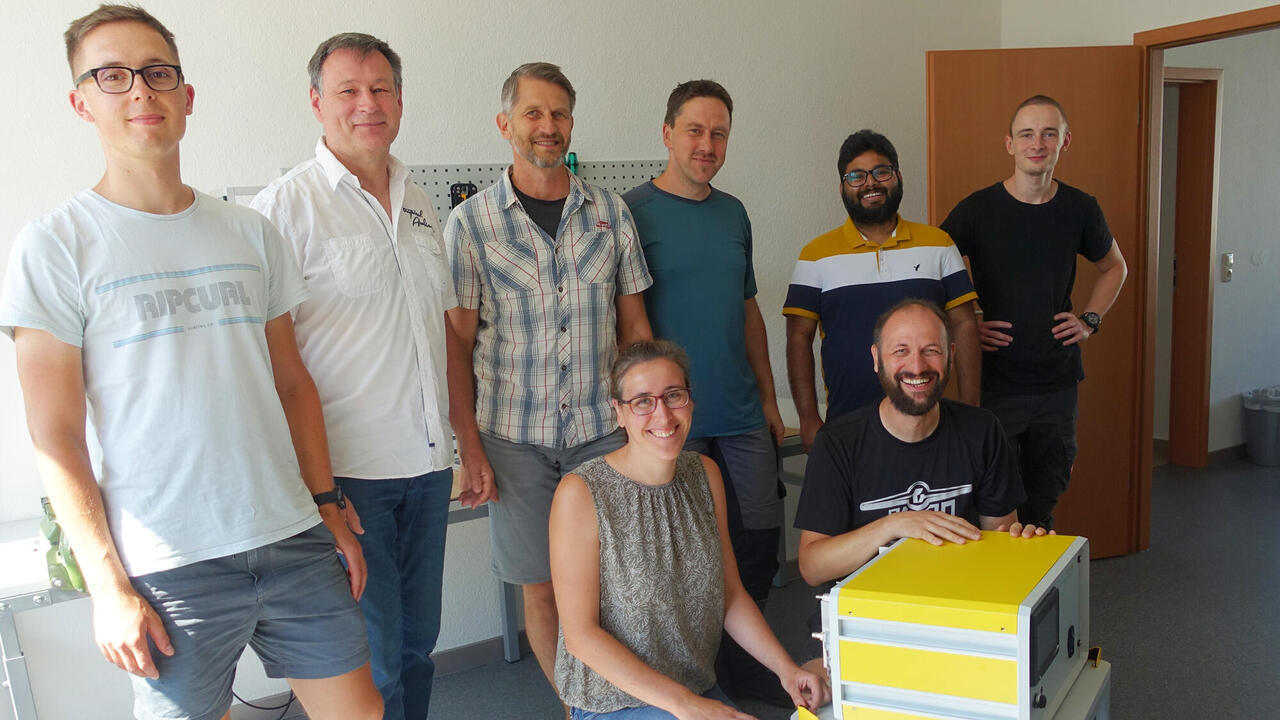

As a technology-oriented company, Topas employs a large number of different engineers. In addition to development engineers like Jan Müller, many project and application engineers as well as designers work at the expert for aerosol and particle measurement technology. They are responsible for system development, installations at the customer’s site or preparations of devices for series production. Application engineers use the fully developed equipment for various tests, make adjustments to suit the customer’s needs and are responsible for the transfer, installation, maintenance, and troubleshooting of test stands and systems in direct contact with the customer. Project engineers are responsible for the development of most Topas test systems and take the lead in the entire process from general project coordination to implementation. Depending on the customer’s requirements, no modifications — or only very minor ones — may be necessary to the test stand and occasionally major modifications or completely new developments may be required. At this point, the development engineer and his team come into play again for certain test systems. The eight developers perform various tasks in the areas of pre-development and post-development. Jan Müller has been the head of the team since 2022 and is therefore no longer only responsible for his own projects but also for organizing all tasks in the area of research and development.

Independence through the deep value chain

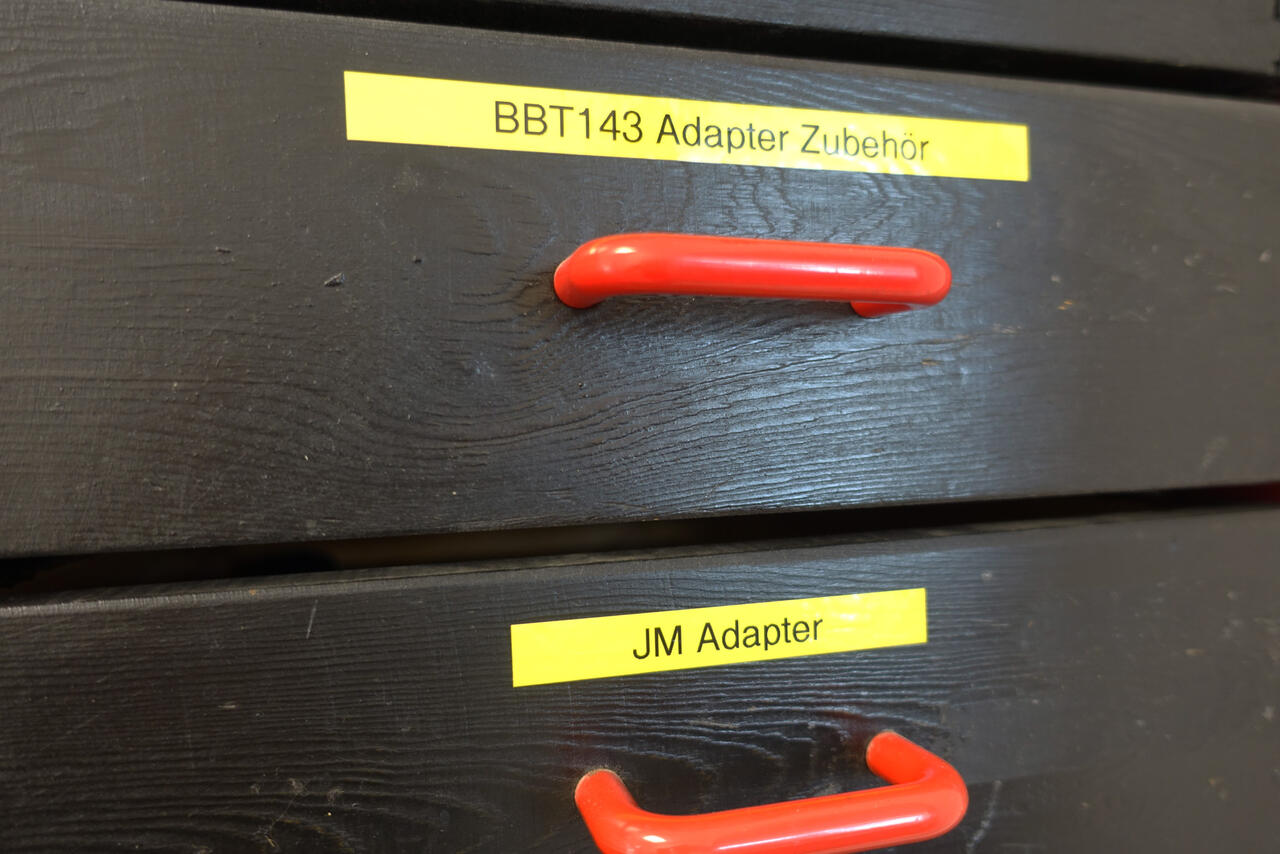

The close links between the development team and other departments illustrate the deep value chain at Topas, which makes the Saxon company independent and special. The development engineer appreciates the regular exchange with departments such as Marketing & Sales, the workshop, design or other project engineers and the management. Requests for solutions, development ideas, market potential and test results are discussed here on flat hierarchical levels. This is how the technical creations are born for which Topas is known and for which the head of R&D is always enthusiastic. Among his favourite projects during his tenure at Topas is the development of the BBT 143 Blow-By Test stand, which is used in engine development to measure exhaust gasses. He has also been instrumental in the development of the ATM 228 Atomizer Aerosol Generator or the VDS 562 Variable Dilution System. His drive is to make devices operable and to actually see his inventions in the marketplace. “I like devices that don’t disappear in the basement but are actually useful to the customer. And that, in a market, that is extremely exciting for me,” answers the engineer when asked what he likes most about his work.

And when Jan Müller isn’t working on technical solutions? Then he’s out on his bike or passionately playing the bass at city festivals and other occasions with his band B1000, specializing in the best of German Eastrock. By the way, the rehearsal room is located two floors below his office – so work is never really far away.