Generation, conditioning and monitoring of coating aerosols with our technology solutions

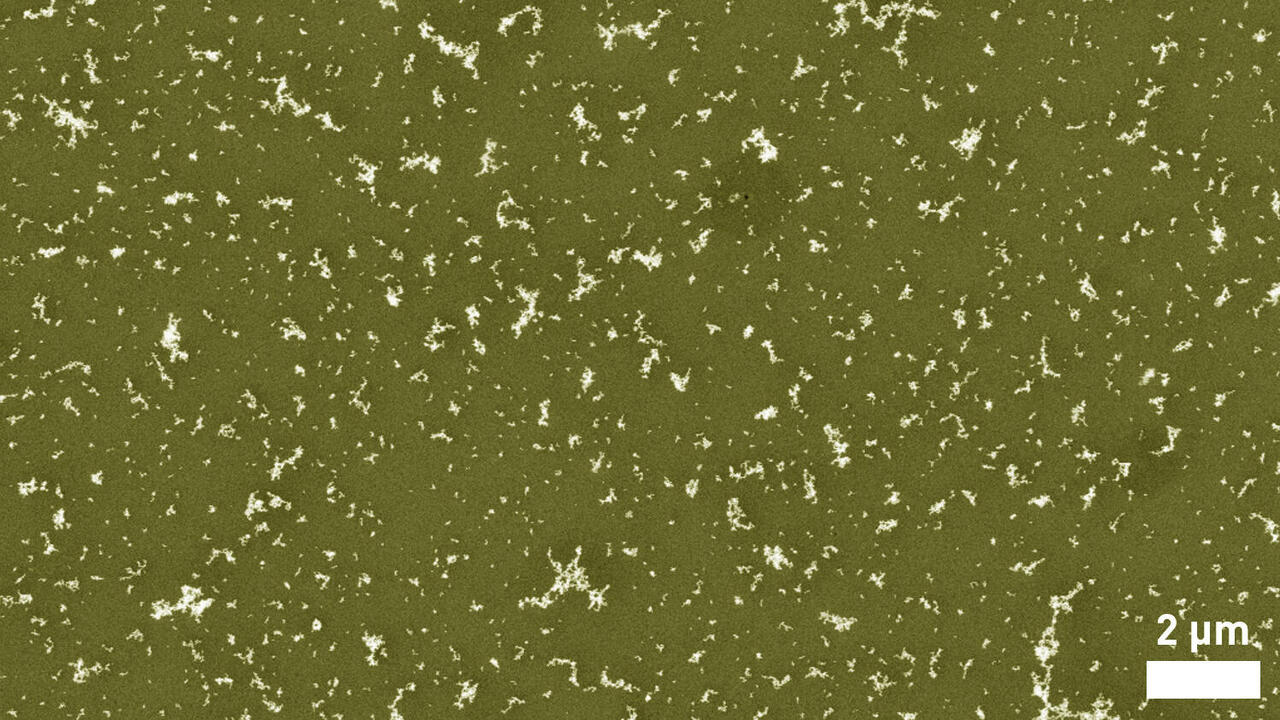

Product surfaces are coated to induce defined functional properties (e.g., repulsion of dirt, abrasion resistance) and/or to enhance their appearance. In addition to permanent coatings, temporary coatings are also in demand in certain industries for specific requirements, such as for the protection of products in production, for testing purposes of materials/components/devices (for stress tests, functional tests) or for the delivery of medical drugs.

Today, there are numerous technical processes for the production of coatings. These differ primarily in the type of coating application (e.g., chemical, mechanical, thermal). Depending on the kind of process, aerosols can be the starting point for the application of the layer, or an intermediate product. A wide variety of aerosol technologies are in use for this purpose.

Aerosols and gaseous reactants (precursor substances) for coating purposes can be generated or provided by, among other things:

- pneumatic dispersion of powders (SAG series)

- pneumatic dispersion of liquids, solutions and suspensions (ATM series)

- combustion processes (NPG 280)

- chemical gas phase reactions

Depending on the application, it can become necessary to modify specific properties of the coating aerosol through concrete measures, for example to influence particle separation or to improve the quality and homogeneity of coatings. These measures include, for example:

- adjustment of the particle concentration in the aerosol (targeted dilution via dilution systems of the DIL series, DDS 560 or VDS 562)

- change of the aerosol charge state (by means of unipolar charging or neutralisation by means of EAN 581).

- removal of interfering substances such as hydrocarbons, volatile organic compounds (with TDD 590 thermodenuder) or water (with diffusion dryer DDU 570/L, DDU570/H)

The quality of aerosol-based coatings also depends fundamentally on the properties of the coating aerosol, so that these often require metrological monitoring. Depending on the application, various aerosol analytical measuring instruments can be used for this purpose:

- light scattering spectrometer (LAP 322, LAP 323) according to ISO 21501-1 for time-resolved monitoring of particle size distribution and concentration

- process aerosol monitor (PAM 510) for monitoring particle concentration and mean particle size

- aerosol photometer (PAP 610, PAP 612) for the characterisation of particle mass concentration of higher concentrated aerosols

Complete Topas systems can also be used for specific coating tasks. These include, among others:

The US National Aeronautics and Space Administration (NASA) is conducting studies on the suitability of construction materials for use in space and on the performance of solar collectors. For this purpose, NASA operates the SAG 410 dust generator in combination with lunar dust surrogates.

The focus of cancer research for the treatment of peritoneal cancer is on investigations into the homogeneity and effectiveness of drug deposition of aerosolised chemotherapeutic agents in the abdominal cavity. A study conducted by the Ruhr Universität Bochum and the Technische Universität Dresden used a modified ATM 220 with a highly concentrated chemotherapeutic agent and various tracer substances.