AFC 136 Test System

AFC 136 Test System for production control of filter elements (e.g. exhaust filter, HEPA filter)

For the purpose of 100% inspection of the integral filter separation efficiency during production, especially for exhaust filters and HEPA filters used in vacuum cleaners and mobile air cleaners.

Production control demands for short test cycles while using robust, compact, service-reduced and safe technologies. A test cycle includes therefore the supply, the analytical characterisation and the re-moval of the test specimen. Due to its measurement concept and high degree of automatisation, the AFC 136 enables reliable testing with measurement times of 30 s.

To ensure a full traceability, determined test data can be integrated directly into in-house databases by combining the filter test system with techniques for test specimen identification (e.g., bar code or QR code scanner).

To ensure a full traceability, determined test data can be integrated directly into in-house databases by combining the filter test system with techniques for test specimen identification (e.g., bar code or QR code scanner).

download

product sheet AFC 136 PCBenefits

- test system designed for 24/7 operation with automated safety functions

- short test cycles (supply, analysis, removal) for separation efficiency and pressure drop

- quality criteria for separation efficiency and pressure drop are freely configurable

- minimal loading of test specimen (higher lifetime of products)

Applications

- production control of integral separation efficiency of exhaust particle filters (GPF, DPF)

- quality control of HEPA filters or filter cartridges of e.g. industrial vacuum systems

- research and development on any small air filter elements

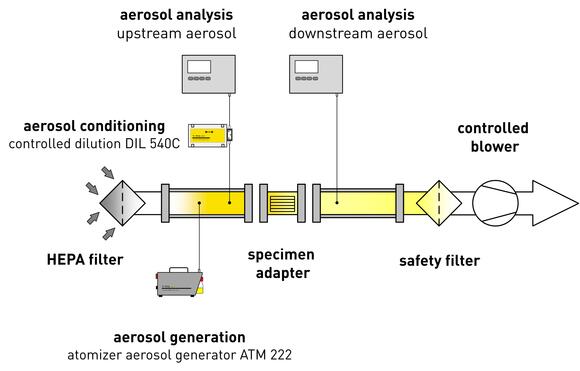

A defined volumetric flow rate is sucked by a controlled blower from the environment through a HEPA inlet filter, the test duct and a safety filter. The test duct is composed of three functional sections, i.e., sections for i) the generation and characterisation of the test aerosol (upstream aerosol), ii) the incorporation of the test specimen (specimen adapter) and iii) the characterisation of the downstream aerosol.

| Parameter title | Unit | Value |

|---|---|---|

| test flow rate | m³/h | 40 ... 440 (1200) |

| measuring range, particle size | µm | 0,1 ... 1 (OPC) |

| measuring range, particle size | µm | 0,001 ... 1 (CPC) |

| test cycle duration | s | approx. 30 |

| test aerosol | - | customer-specific (DEHS, ...) |

| dimension of test specimen | - | diameter ≤ 300; length ≤ 850 |

| compressed air supply | bar | 4,0 ... 6,0 |

| power supply | - | 3 x 400 VAC, hard-wired, rated current 30 A, pre-fuse 32 A |

| inner diameter of duct | mm | 150 |

| aerosol-analytical instruments | - | customer-specific (e.g. OPC, CPC, ...) |

| sensors, others | - | temperature, relative humidity, air pressure |

| dimensions (w × h × d) | mm | 2800 × 2100 × 1200 |

| weight | kg | approx. 800 |