AFS 151 Test Systen

AFS 151 Robot HEPA/ULPA Filter Scanning System

The AFS 151 filter scanning test system is used to determine the integral and local particle filtration efficiency and leak detection of 2-dimensional and 3-dimensional filter elements.

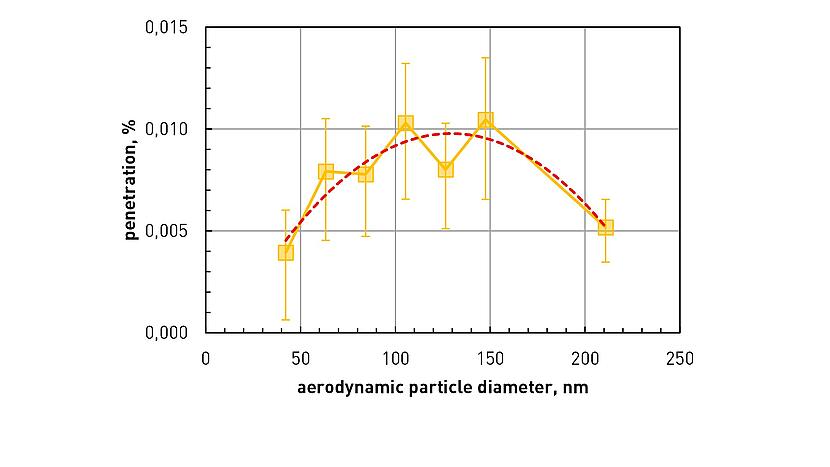

Due to the modular setup, different types of test aerosols such as DEHS, paraffin oil and PSL can be used. By default, optical particle counters (OPC) are used for efficiency testing and leak detection, but SMPS measurements or tests with DMA-classified aerosols in combination with condensation particle counters (CPC) can be performed as well. The initial test system is designed for HEPA/ULPA panel filters and cartridges used at moderate volume flow rates. Upon request, this setup is subject to be up-scaled to higher flow rates.

Standards

ISO 29463-5

ISO 29463-4

download

product sheet AFS 151Applications

- product development and quality control of HEPA/ULPA filters

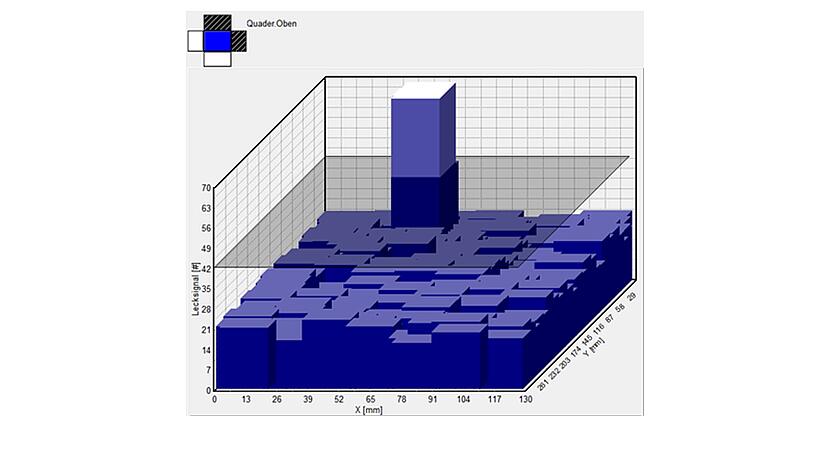

- scanning of panel filters and filter cartridges

- 3-dimensional scanning of V-bank filters

The multi-functional test setup of AFS 151 allows integral filtration efficiency tests by using a suitable hood assembly in terms of a quick production control check. Furthermore, filters can be scanned on leak detection and local efficiency in moderate time intervals using a polydisperse test aerosol. Working stepwise with a classified aerosol, reliable MPPS curves can be determined during filter development.

| Parameter title | Unit | Value |

|---|---|---|

| test flow rate | m³/h | 1 ... 300 |

| measuring range, differential pressure | Pa | 50 ... 5000 |

| scan speed | mm/s | 5 ... 100 |

| dimension of test specimen (w × h × d) | mm | panel filter (50 ... 500 × 30 ... 500 × 7 ... 280), filter cartridges (40 ... 350 × 40 ... 350 × 45 ... 600) |

| operating medium, aerosol substance | - | DEHS, paraffin oil, PSL |

| operating medium, gas/air - compressed air supply | bar | max. 6,0 |

| power supply | - | 3 x 400 VAC, 32 A |

| aerosol generation technology | - | ATM 222 (DEHS), ATM 233 (paraffin oil), ATM 240/L (PSL) |

| aerosol measurement instruments | - | Optical Particle Counter (OPC), Condensation Particle Counter (CPC), Scanning Mobility Particle Sizer (SMPS) |

| dimensions (w × h × d) | mm | 4000 × 4000 × 3000 |

- ATM 222 Atomizer Aerosolgenerator for DEHS

- ATM 233 Atomizer Aerosolgenerator for paraffin oil

- ATM 240/L Atomizer Aerosol Generator for PSL