Our field of operation

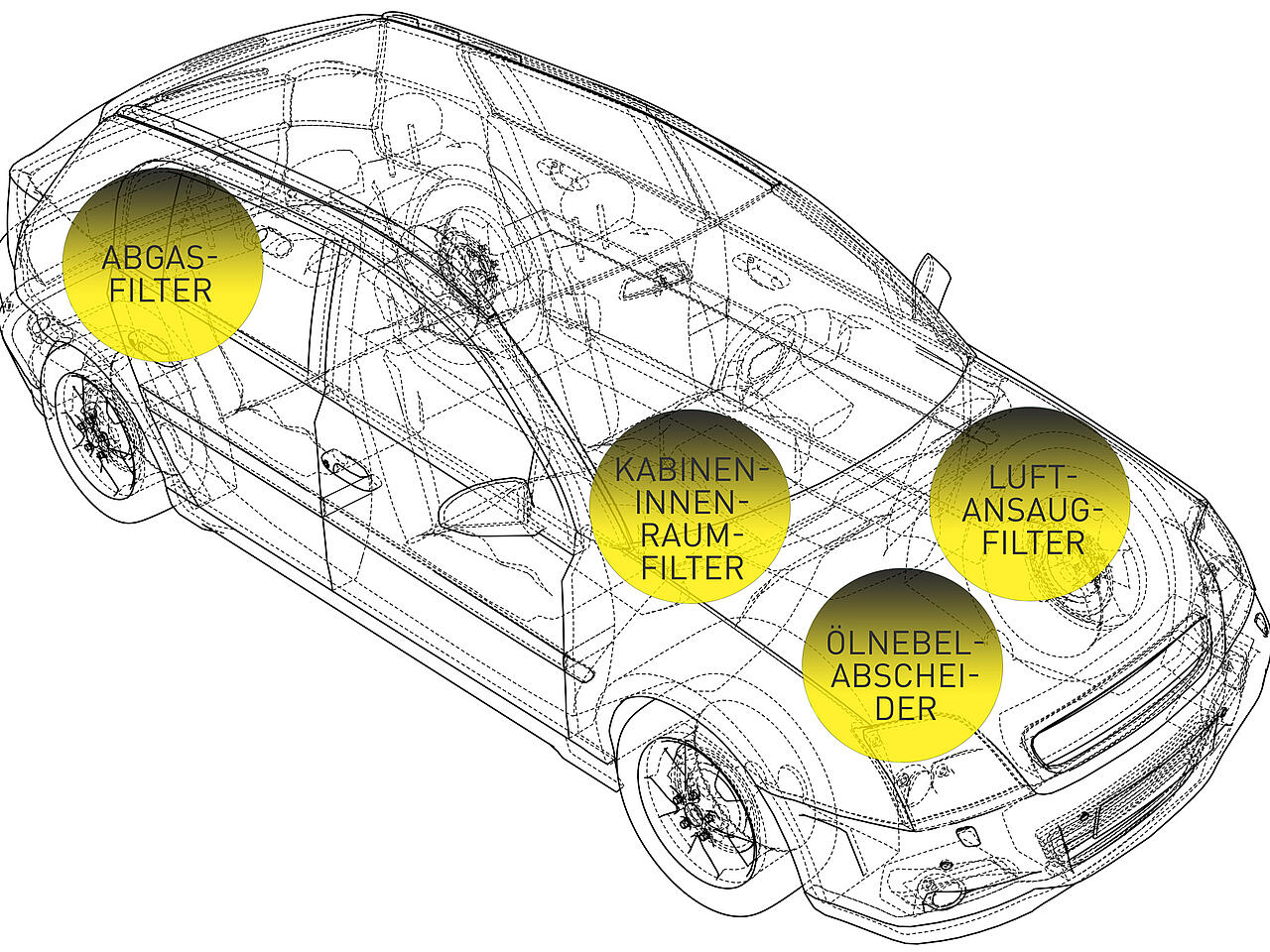

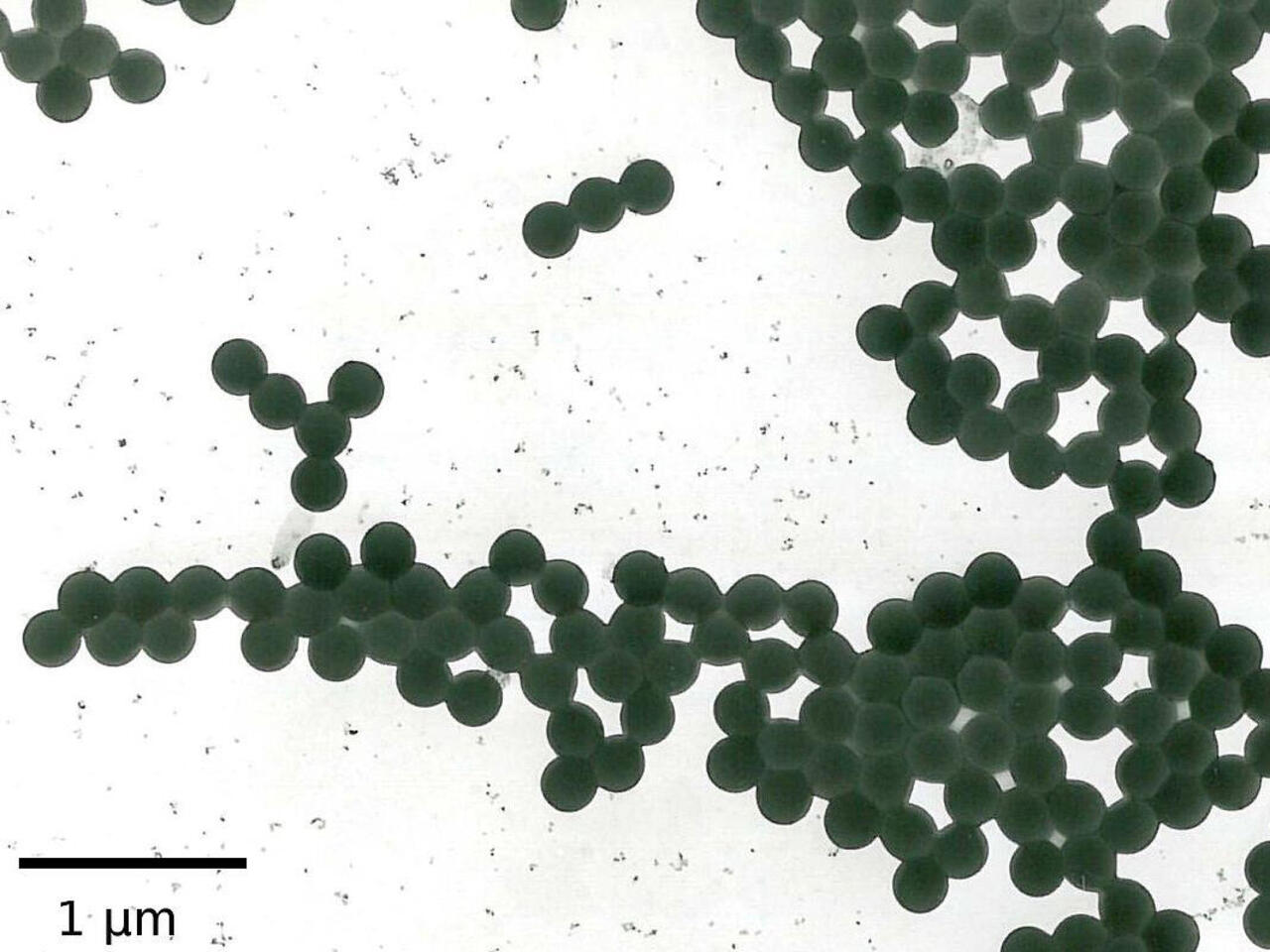

Since more than 30 years, technology-oriented particle, analysis and sensor systems have been developed, designed and manufactured under the name Topas. They can be used to generate, condition and analyse test and reference aerosols. In addition, more than 60 series devices and 20 test systems of our medium-sized Saxon company have been widely used and proven for the classification and testing of filters and filter media in worldwide industry and basic research for decades.

Adaptable, dynamic, communicative: our new dilution system DDS 560/C

High flexibility and a dynamic system that does not restrict customers to a single volume flow rate and dilution factor are key features of the DDS 560/C. It has now been further developed by our engineers and comes with a clear display layout. This offers options for customised settings and thus extended access to internal device parameters such as the dilution factor or the volume flow. The existing external interface enables the documentation of experiments because setting parameters are saved over time. A must-have in every laboratory: The DDS 560 is the dilution system that adapts to your needs. Regardless of whether you work in aerosol research, toxicology, cleanrooms, or filter testing.

See all advantages and fields of application at a glance in our new product video.

The BSFZ seal is exclusively provided to companies that carry out research and development within the meaning of the "Forschungszulagengesetz" (act on research grants). We have received it for the "Development of a novel method for signal evaluation and processing for optical aerosol spectrometers".

Best conditions for your own tests in our premises

In the Topas TIC, our Technical Innovation Center, the doors are open to you: Get an impression on state-of-the-art filter test systems, carry out your own measurements at your air filter products and learn more about the key performance parameters of your product. Qualify your products yourself this way. In addition, training, e.g., for new operators on these systems, can also be provided by experienced Topas engineers. In the recently opened home of the Topas Academy, place of activity of our developers and researchers, modern training rooms and demonstration and measurement technology are available for your projects. Please contact us or read more at Technical Innovation Center & Topas-Academy!

![[Translate to English:] Aerosolgeneratoren](https://www.topas-gmbh.de/fileadmin/user_upload/Fotos_Collagen/Sonstiges/S-Startseite-Slider-Produkte-Topas.png)

![[Translate to English:] Vertriebskarte](https://www.topas-gmbh.de/fileadmin/user_upload/karte.png)